| |

|

|

|

|

|

| |

| PROCESS DESIGNED FOR PRODUCTION OF THERMO MECHANICALLY TREATED BARS (T.M.T BARS) IN RE-ROLLING MILLS. |

| |

| THE COOLING PROCESS |

|

|

| |

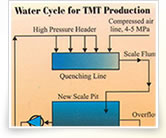

In bar mills, directly after the last rolling stand, the bar passes through the “T.M.T PROCESS” Charged Quenching System achieving a short and intensive cooling of the surface. Because of the reduction in the temperature at a rate higher than the critical rate for marten site quenching the surface layer of the re-bar is converted to a hardened structure while the core remains austenitic. After the intensive cooling, the bar is exposed to air and the core reheats the quenched surface layer by conduction, therefore tempering the external marten site.

The thermal profiles of the surface and core merge at the ‘so called’ equalizing temperature that together with the final rolling temperature is the most important parameter to achieve the required mechanical properties. Finally, when the bar is discharged on to the Cooling Beds, the remaining austenite transforms into a very fine grained pearlite structure. The process being offered is the most efficient system available. The Cooling pipes consist of specially designed nozzles, which assure a high degree of heat exchange rate between cooling water and the traversing bars. The design ensures the elimination of the steam layer generated on the material surface. The system is designed keeping in mind mill characteristics and space available.

Water flow in the Quenching pipes is designed both in parallel flow and counter-flow and depending upon different parameters. |

| |

|

| |

| SPECIAL FEATURES OF TMT BARS |

|

|

Higher strength combined with better elongation values as compared to conventional CTD bars. |

|

Excellent Weld-ability because carbon is restricted to below 0.20%. |

|

Resistant to fire hazards as there is no loss of strength up to 500 deg. C. |

|

Excellent Ductility and higher fatigue strength, which makes it suitable for structures and foundations subject to dynamic and seismic loading. |

|

Better Ductility and Bend-ability makes it easily workable at site. |

|

Fulfils Bond requirements as per IS: 456/78 and IS: 1786/85. |

|

| |

| RANGE OF TMT PRODUCTS |

| Be it high rise buildings, bridges or dams, the high strength TMT bars offer a panacea for all applications. Our process is capable of following product range: |

| |

| DIAMETER: 8, 10, 12, 16, 20, 25, 28, 32, 36, 40 & 45mm. |

| GRADES: Fe-415, Fe-500, Fe-550. |

|

|

| High Strength Corrosion Resistant TMT bars for combating marine corrosion in Grade A and M. Process will guarantee production of TMT Bars in International Standards like German-Bst 420 S/ 500 S of DIN488, British Gr.460 of BS 444919798, Egyptain Standard 262/1988 Gr.36/52 and 40/60. Fe-415.500 & 550 of IS:1786/85, JIS G 3112 1975 SD 30, 35, 40 & 50. Swiss topar 550 S of SIA 162, French Fe E50 of NF A35-016. |

|

| |

| BASIC EQUIPMENT LIST |

| Quenching Pipes ( with built-in high pressure water spraying and specially designed wear resistant nozzles). The cooling pipes are for a batch of bar size ranges 8 to 12 mm, 16 to 36 mm, High-pressure cold water centrifugal pumps and hot water centrifugal pumps. |

|

|

|

|

|

|